Quality Inspections with Multi-ROI

Manufacturers are being challenged by fluctuations in consumer demand, while facing heightened pressures on machine utilization, production efficiencies, and quality control. At the same time, they are inundated with headlines about new automation and Industry 4.0 solutions. During these volatile times, manufacturers are looking for ways to make their factories more robust against both fluctuating demand and changes in workforce. Now, more that ever, they are ready for new technology, but it must be flexible, affordable and easy to deploy.

Earlier this year we released our Neurala VIA software, an integrated solution that helps manufacturers improve quality inspection on the factory floor using their existing hardware. Since then, we have developed a global partner program to help manufacturers adopt AI-powered quality inspections quickly and efficiently.

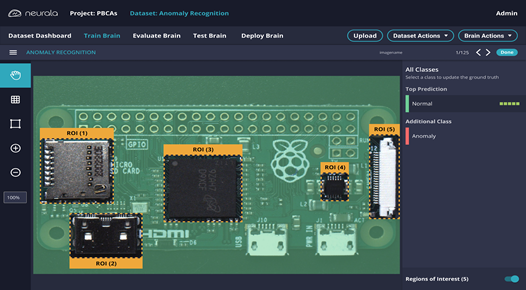

The most recent development for VIA is the ability to inspect multiple regions of interest (ROIs) within an image from a single camera. Multi-ROI inspections can be used for individual part of component inspection when many are in the same field of view, it could be used to inspect multiple areas during a surface inspection, or it could be used to be able to inspect smaller areas to find smaller defects with a high resolution camera. This ability is especially critical in electronics and PCBA inspections, where you need to inspect multiple components such as resistors, capacitors, solder points, HDMI ports, RAM or the USB controller. Below is an example of a PCBA inspection with multiple areas being inspected for quality (e.g. the correct component in the correct orientation) with Neurala VIA. Knowing if the part is good or bad overall is important, but understanding what is wrong with that piece is just as critical.

From the image above, you can see PCB’s are complex items to manufacture, and multiple points of inspection are required before the product can pass. A small, overlooked defect could render the PCB useless and cost manufacturers significant losses. Using this detailed information, the board can be reworked in the case of a defect, and trends can be examined to determine if there is a root cause to prevent similar defects from occurring in the future.

While Inspection methods may vary among manufacturers, AOI machines have long been the industry norm. These AOI machines are not only an expensive up-front investment, they need to be specially programmed and require specific knowledge of the machine. The machines often require a dedicated, skilled operator. They can sometimes struggle with high volume applications, are not flexible, and take time to update for new variants. In the common scenario of high mix, low volume electronics manufacturing, Neurala VIA shines by enabling the user to train quickly and define good vs. bad product using very little data. VIA’s Multi-ROI capabilities drastically drive down the cost per inspection point. With VIA performing inspections, manufacturers are able to inspect things such as product or component location, proper packaging, and product orientation, all with a cost effective software solution.

Interested in learning more about the advantages of Neurala VIA? Speak with one of our vision AI specialists.