AI and Smart Automation Conference: Max Versace on Vision AI for the Factory Floor

Last month the Association for Advancing Automation (A3) hosted a virtual conference focused on the power artificial intelligence (AI) and what it can offer to the manufacturing process – from production optimization and predictive maintenance to intelligent inspections, and beyond.

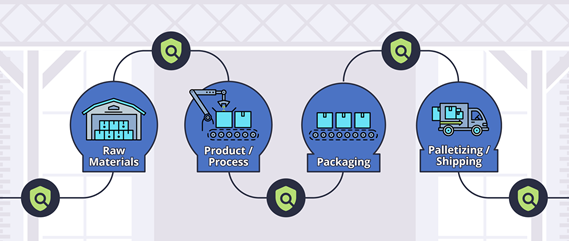

Neurala CEO and co-founder Max Versace spoke about the accelerated adoption of AI in manufacturing, and the potential for vision AI on the factory floor, which goes beyond the capabilities of traditional machine vision. From the raw materials coming in, to the palletizing of products shipping out, Neurala’s vision AI software, VIA, offers many opportunities for improved quality inspection throughout a production facility.

Watch the video of his presentation

Max also shared customer insights about the following use cases for vision AI:

- Electronics: unlike expensive, hard-to-program AOI machines, vision AI excels at high mix, low volume product lines, simplifying the set-up process and lowering the cost per inspection point.

- Surface inspection: while difficult for traditional machine vision, vision AI can identify a wide variety of defects (i.e. scratches on sheet metal), catch anomalies that aren’t specifically trained for, and quantify subjective quality assumptions.

- Packaging: whether it’s primary, secondary or tertiary packaging, vision AI can enable multiple inspection points with minimal set-up, catching errors earlier, and reducing production downtime.

Advantages of Neurala VIA

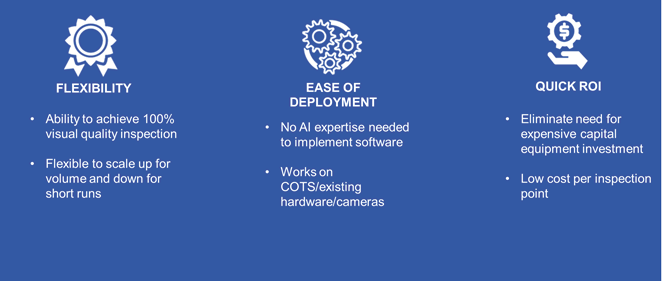

And finally, Max outlined the advantages of Neural VIA software for improving quality inspection, including flexibility, ease of deployment and quick ROI.

Want to learn more about how you can start improving quality inspections with VIA? Speak with one of our vision AI specialists.