Leveraging AI to produce over 1 million meals

Leveraging AI to produce over 1 million meals

apetito is the leading food producer for the health and social care sector, supplying to the elderly and some of the most vulnerable in society, via Britain’s National Health Service, care homes, meals on wheels, as well as to individuals in their own homes. Great quality food, meeting various nutritional requirements and dietary needs is at the heart of what they do. Ensuring that the customer receives the right meal, with all elements in the right proportions is crucial – hence the focus on working with AI.

The Challenge

While producing in excess of 1 million meals a week, apetito was receiving complaints about missing meal components. They needed a solution that could efficiently detect errors in the products coming off the line, without compromising efficiency or cost – better yet, improving both.

The Solution

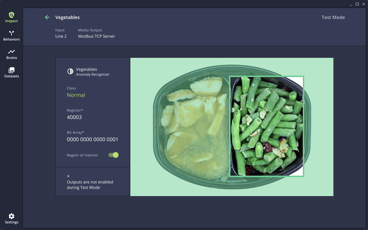

After exploring several solutions to the problem, apetito began working with Neurala. They began utilizing Neurala VIA (Vision Inspection Automation) – our easy-to-use vision AI to detect inconsistencies and defects before products leave the factory. Through this collaboration, apetito is now confidently delivering the highest quality product to their customers.

"Throughout this AI-building journey, we’ve spoken with other companies in similar situations, and are yet to find anybody in the food industry that is leveraging AI like we are with Neurala. We’re very much breaking new ground together. " - Kevin McDonagh, Operations Manager, apetito

Download the Case Study and learn more.

FAQ

- How does Neurala VIA work in detecting missing meal components and ensuring the quality of apetito's products?

apetito recognized the power of AI even before working with Neurala. To begin optimizing performance and automating visual inspections, apetito employed a graduate student to develop a Raspberry Pi-based solution to monitor one production lane. Photos of good and unacceptable products informed models connected to an output signal that could blow rejects off the lane. As a result, apetito no longer needed to allocate an individual to this function, enabling them to be redirected into more productive areas, effectively saving over £15,000 in labour per year.

- What other benefits or outcomes have resulted from apetito's adoption of Neurala VIA, such as improvements in production efficiency, reduction in waste, or enhancement of overall product quality?

apetito was able to develop a model that can flag missing components with 100% accuracy, laying the groundwork for easy expansion to additional production lines, with the ability to build new AI brains in 10-20 minutes and immediately begin testing, ultimately saving costs and addressing workforce shortages while increasing product quality.