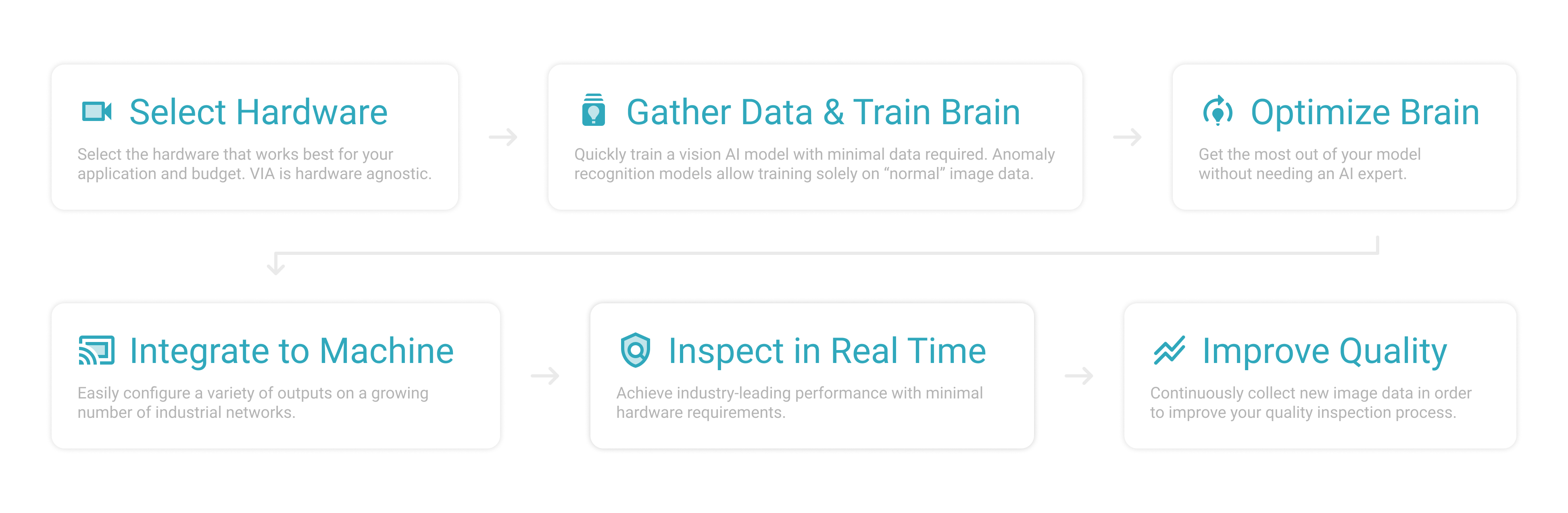

Neurala’s Vision Inspection Automation (VIA) software helps manufacturers improve their vision inspection and quality control processes to increase productivity, providing flexibility to scale to meet fluctuating demand. Easy to set up and integrate to existing hardware, Neurala VIA software reduces product defects while increasing inspection rates and preventing production downtime – all without requiring previous AI expertise.

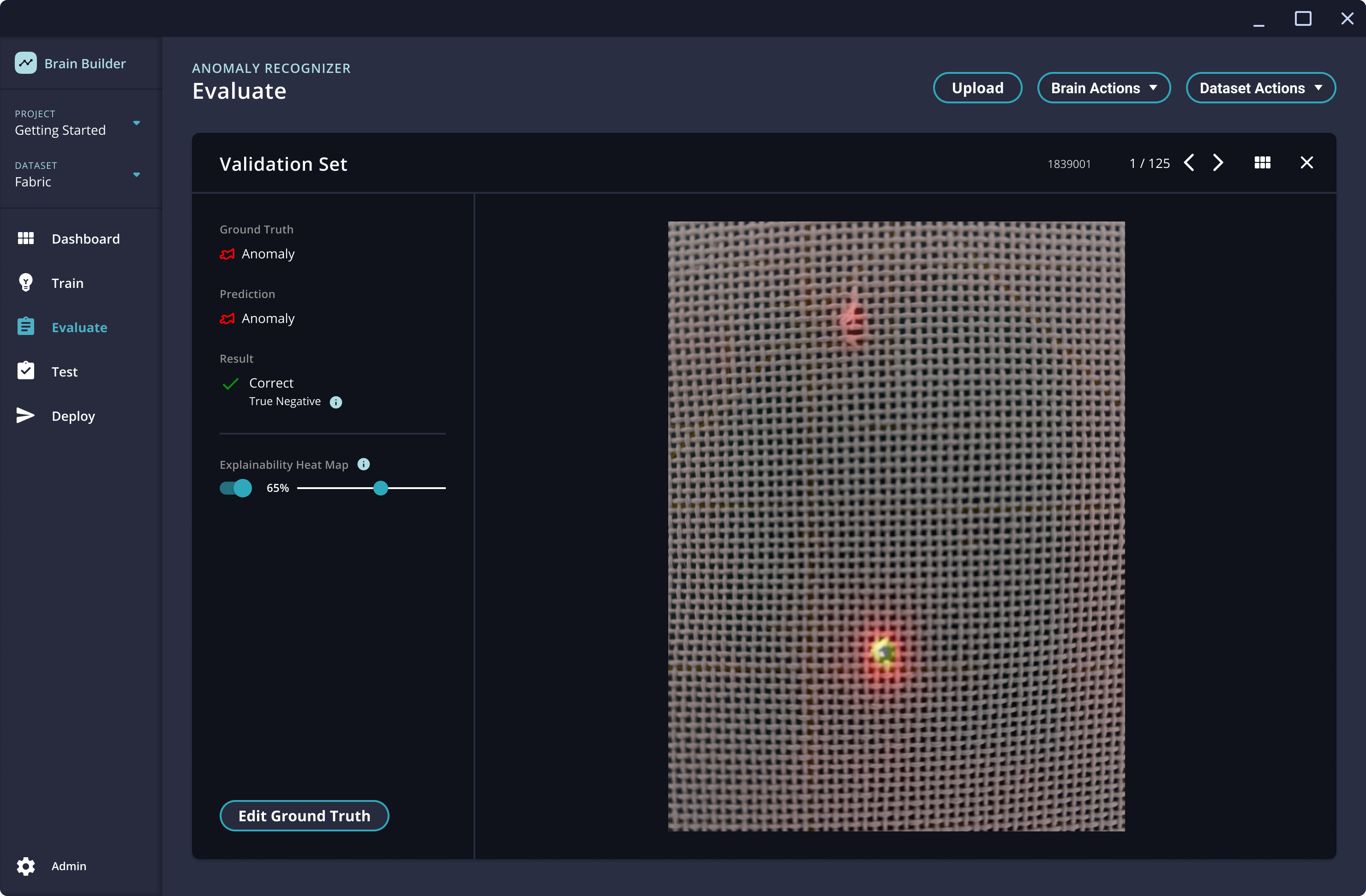

Neurala’s Explainability feature highlights the area of an image causing a vision AI model to make a specific decision about a defect. With this detailed understanding of the workings of the vision AI model, manufacturers can build better performing AI models that continuously improve processes and production efficiencies.

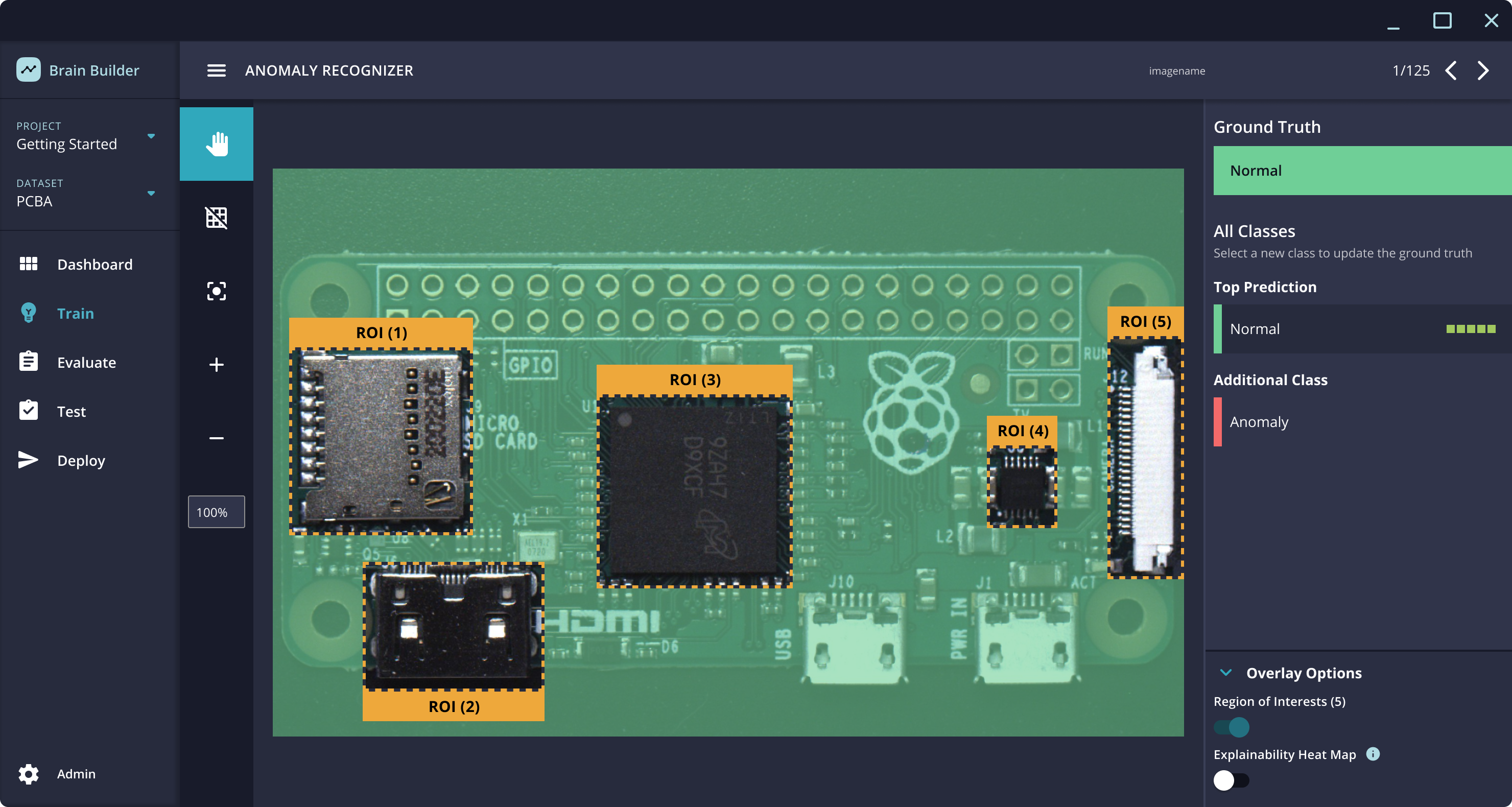

Neurala's Multi-ROI (region of interest) feature helps ensure that all components of particular interest are in the right place and in the right orientation, without any defects. Multi-ROI can run from a single inspection camera, which dramatically reduces the cost per inspection, without slowing down the run time.

Defects that are easy for a human to see can be difficult for machine vision to detect. Adding vision AI dramatically increases your ability to detect challenging defect types such as surface anomalies and product variability. Neurala VIA helps improve inspection accuracy and the percentage of products being inspected. You can build data models in minutes, then easily modify and redeploy for changes on the production line.

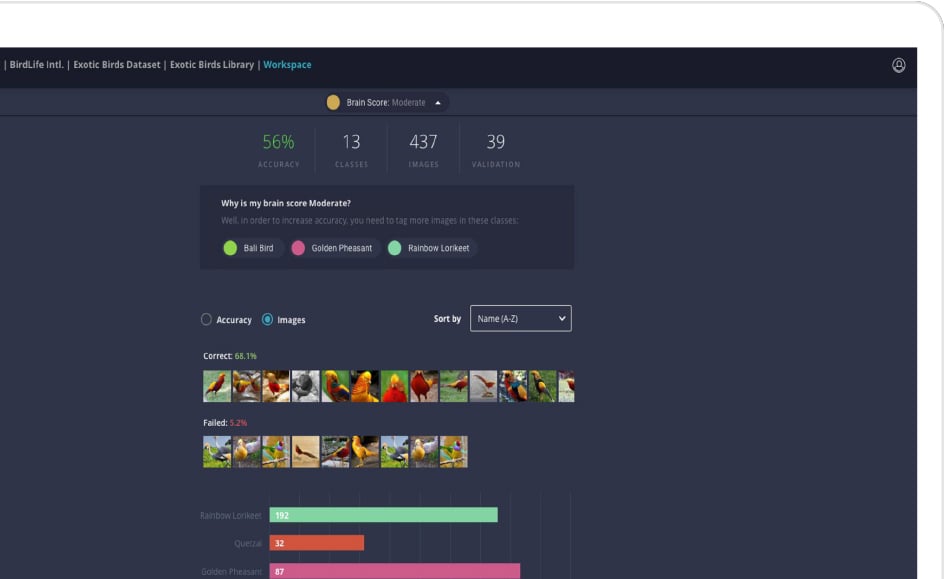

Training robust vision models is complicated. We provide insights all along the stages of development to help you improve performance even if you’re an AI beginner. Once the brains are deployed, we provide customer insights so you can better understand

Integrate vision AI into your quality inspection process for improved defect detection.

Make your robots more useful and flexible with custom vision AI on the edge.

Empower intelligent drone inspections and operations with AI software.

Our commitment to building a company that is defined by innovation, technology and AI is greater than ever before, and our partnership with Neurala represents a key step in that commitment.

Dario Rea, Director of Corporate Research & Innovation

IMA Group

Partnering with Neurala gives us continuously evolving capabilities. Neurala's product development allows us as integrators to provide unique and innovative solutions, and have a partner supporting us in that effort.

Brian Page, Senior EngineerJ.A. King

Today’s manufacturers are under pressure to meet fluctuating customer demand and deal with challenges in workforce and machine availability. We’ve been able to help relieve that burden by working with Neurala, providing our customers with a cost effective, flexible vision AI solution that will help them automate operations in a way that maximizes their ROI and can be deployed extremely quickly.

M. Haekal Maulana, Head of Division, Engineering & Technology Division

INFINITI GROUP

With Neurala’s VIA, our machine operators can quickly set up complex Visual AI models at the compute edge for quality control and track & trace, without requiring them to have any knowledge of AI or Deep Learning.

Emidio Zorzella, CEO

Antares Vision

As a systems integrator, it is our job to give our customers the best tools to get the job done. With Neurala, we are able to show manufacturers how vision AI can help them solve their greatest pain points in their quality inspection process.

Regina Sozzi, Innovation Manager

Alascom